Sustainable Aviation Fuel (SAF) provides the ethanol industry with great opportunity.

What is Sustainable Aviation Fuel?

Growing Demand for SAF

SAF is expected to add value to ethanol of at least $1.25 to $2 per gallon.

That translates to at least $125-$200 million annually for a typical 100 mgpy ethanol plant.

How is SAF Made?

There are three ways Sustainable Aviation Fuel is made:

1. Ethanol to Jet

Ethanol is a low-carbon, scalable feedstock for the production of SAF.

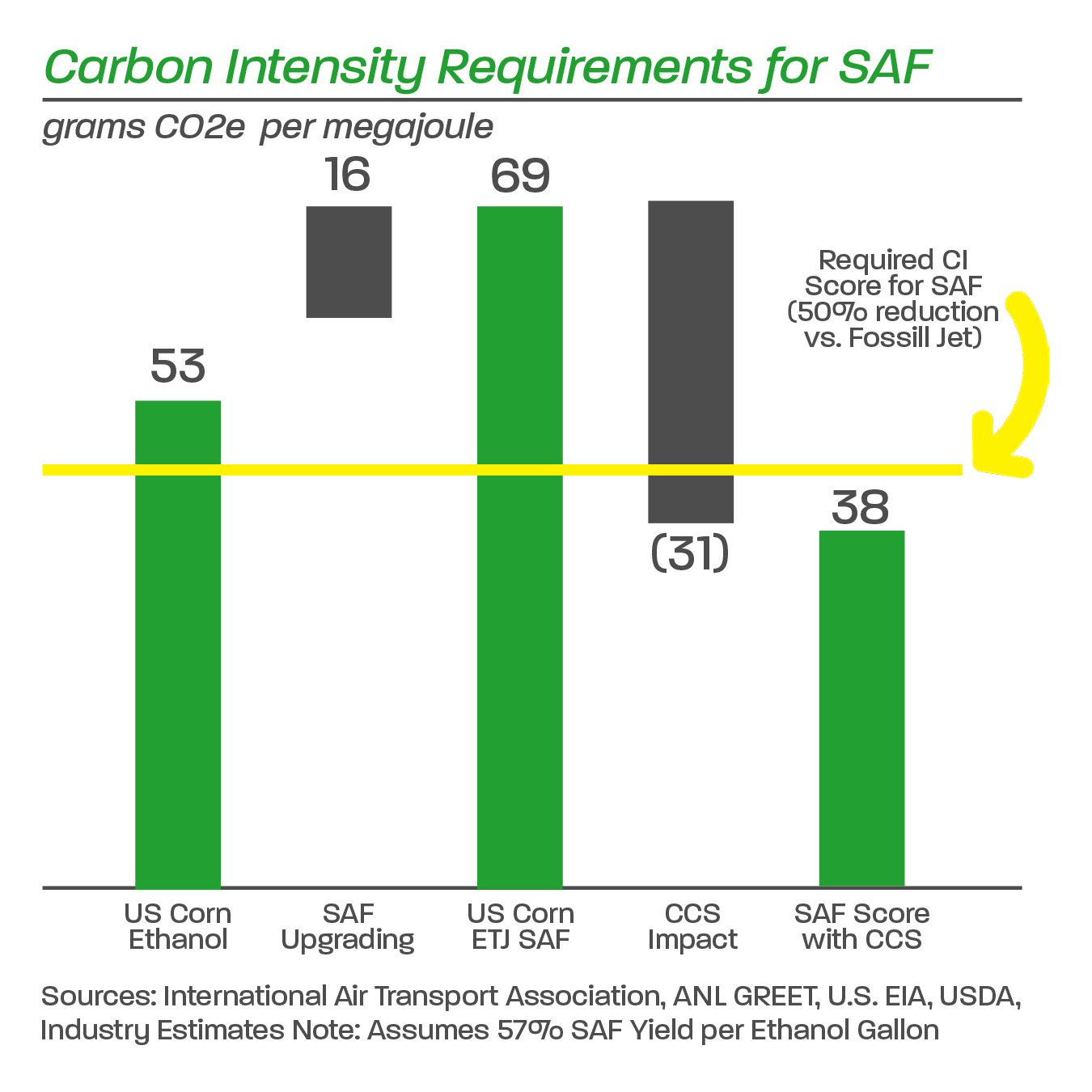

The industry has steadily improved its carbon intensity through efficiency gains and now has the opportunity to make a step-change reduction with carbon capture and storage (CCS).

With reputable ETJ technology providers, ethanol is poised to supply the growing SAF market.

2. Hydroprocessed Esters & Fatty Acids (HEFA)

The vast majority of SAF produced today is through the HEFA process using fats, oils and greases.

While a proven production process, the segment faces headwinds due to feedstock supply constraints and competition for the same inputs as the growing renewable diesel industry.

3. Emerging Technologies

New technologies being developed for SAF include gasification and electricity to liquid fuels.

Technological maturity, high capital & operating costs and large renewable energy requirements present challenges for large-scale deployment.

Carbon Capture and Sequestration creates ample opportunities for efficiencies and value creation throughout the supply chain.

- SAF is a chemically identical drop in fuel currently approved at up to 50% blend rates by ASTM International.

- Upgrading SAF drives investments: Gevo’s Net-Zero 1 South Dakota $1 billion project not possible without CCS.

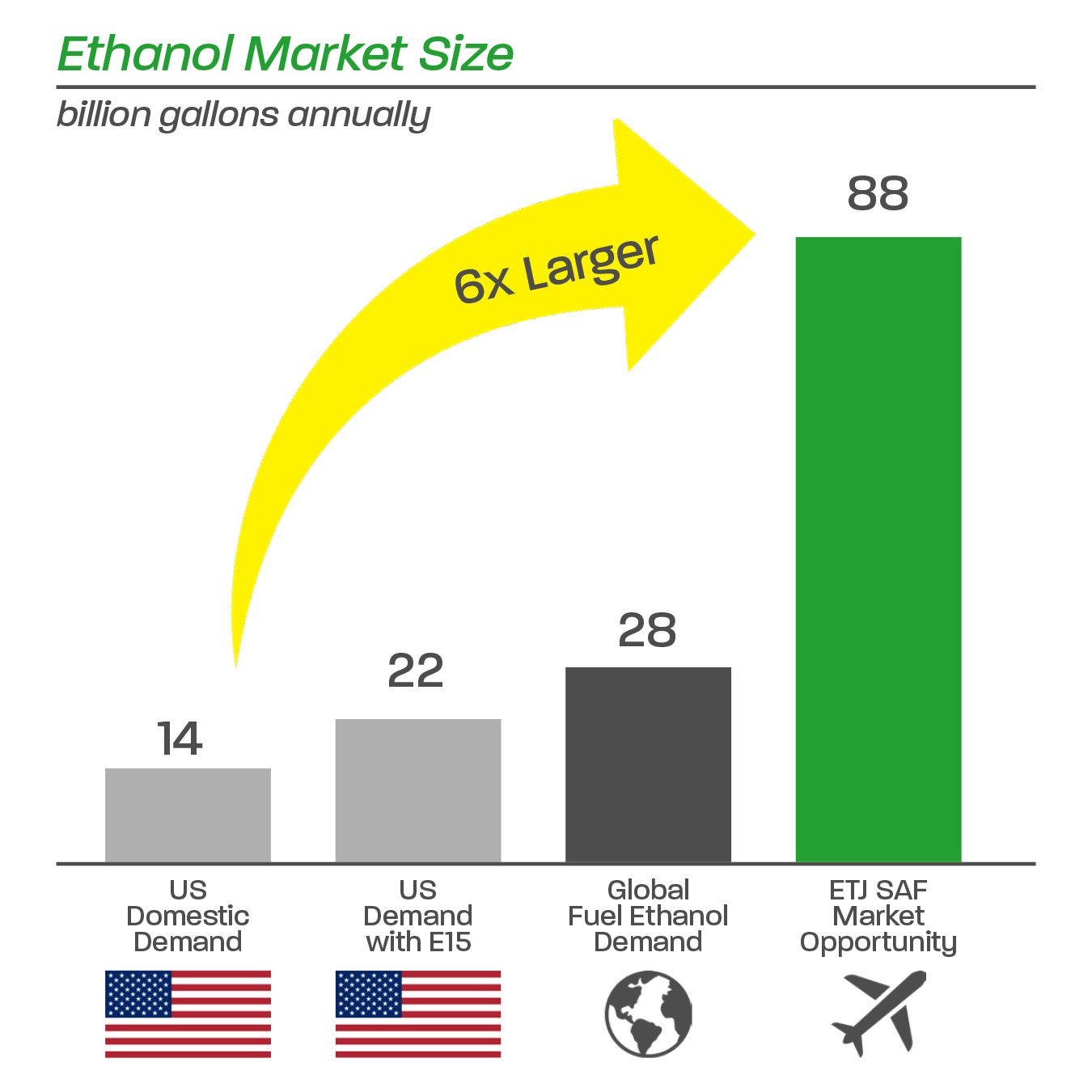

- SAF diversifies ethanol’s major end markets beyond light passenger vehicles.

"Carbon Capture and Sequestration creates market opportunities for ethanol producers providing long-term benefits for the industry and all of agriculture."

Tom Buis, CEO, American Carbon Alliance

The GREET Model Necessary for Sustainable Airline Fuel

Utilizing Carbon Capture and Storage (CCS) will be essential in meeting the United States’ 2030 ambitious SAF goals.

GREET® Model

The Greenhouse gases, Regulated Emissions, and Energy use in Technologies Model

The GREET model is an analytical tool that simulates the energy use and emissions output of various vehicle and fuel combinations.

Developed by the U.S. Department of Energy, the GREET model accurately accounts for technological advancements and climate-smart agricultural practices that reduce the carbon intensity of feedstock production, enhance sustainability and enable the agricultural sector to lower carbon emissions.

The current model that is used to determine Carbon Intensity for SAF is the International Civil Aviation Organization (ICAO) and United Nations standard that is favored by countries like China and Russia. The ICAO has not been updated in over a decade, and actually rates petroleum-based jet fuel better than U.S. corn-grain ethanol, which is patently false.

- • In the Midwest, ethanol producers are eager to utilize CCS to help lower the carbon index score of the fuel they produce as it would open new markets for their product.

- • Ethanol-based Sustainable Aviation Fuels (SAF) will be critical to the aviation industry meeting its emission-reduction goals.

- • The aviation industry demands over 100 billion gallons of jet fuel annually, and that number is expected only to grow.

- • The U.S. Department of Energy has established a goal of generating at least 3 billion gallons of SAF by 2030 and, by 2050, sufficient SAFs to meet 100 percent of U.S. aviation fuel demand.